This is part 4 of the Rod building Tutorial by Michael Newby and Shaun Futter.

PART 1

PART 2

PART 3

THE WRAP:

To ensure even wrap widths on both sides of the guides, take a piece of cardboard and mark the length of the wrap. Put some masking tape at the end of the wrap, to help you with the width of the wrap. Do this on both sides of the guide.

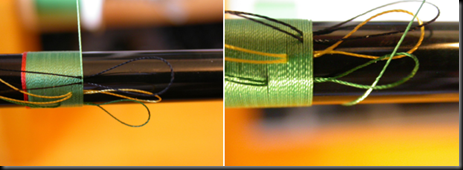

Bring your thread over the front of the blank, and overlap it as shown. Then start wrapping your main thread over the standing part, as illustrated on the right, by turning the blank towards you. The tension should be slight, not too much.

Nowcut the standing part of the thread, and continue wrapping by turning the blank.Make sure the wraps are tightly packed together. The standing part of the thread will now be hidden under the wraps. (NB: This “start” should be on the opposite side of your guides, so that when you look at the guides, this part is under the blank.)

When you get to the guide foot, work slowly…and here’s where your preparation of the guide feet will pay off. If you did it correctly, the thread should climb onto the foot with ease. Continue wrapping until you are about 10 wraps from finishing.

Now (also on the opposite side of the blank from the guide), insert a piece of thread as shown, in a loop. We will use this to tie off our wrap. Continue wrapping and trapping the loop under the thread.

When you get to the end of where you need the thread to be, hold the main thread tight, and cut it off from your spool, keeping tension on it with your one hand. Now put it through your loop, and pull the loop tight, pulling the thread against the wraps. (We are going to use a method called the “disappearing thread trick”.)

Now cut the main thread flush where the loop is, and start pulling the loop. Pull it at an angle as shown. The loop will pull the main thread under the wraps and the thread is now secure. Done!

This is the completed wraps on the stripping guide. You can now remove the strip of tape on the blank in the middle of the guide, that showed us the spacing. If your guide is not completely in line with your “spine” marking, use a little pressure with your thumb to push it into place. This should not be difficult at all.

NB: If you are at all unhappy with your wrap, or if there are frays or “fuzzies” on the thread…cut it off and start again. The finished product will look a lot better.

“FUZZIES”…they will look nasty when finish is applied.

Rather remove the wraps and start again.

Lastly, “roll” and “pack” your thread wraps as shown. For rolling, use a crochet needle. This flattens the thread and fills up any gaps between the threads. Then pack the thread, to ensure it is nice and straight, and tight together.

Wrapping the hook keeper.

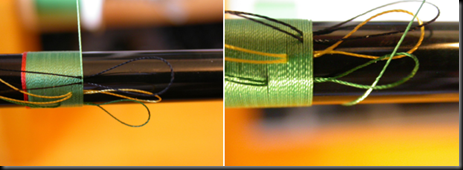

Here is a completed “decorative” wrap (usually in front of the writing on the blank) that encases the writing and specs of the blank, from here to the hook keeper. The main colour is dark green, and the “trim wraps” on both sides are metallic green thread.

STEP 17:

TRIMWRAPS

You may wish to add a decorative touch to your rod, by adding “trim wraps”. These are usually metallic in colour, either gold or silver…but there are many colours to chose from. You could also use a different non-metallic colour of course.

Sage Z-Axis rod, with Gold main thread, and trim wraps in Rust, Black and Metallic Gold.

To do trim wraps, go about as follows:

First start your trim wrap colour thread, and make about four turns around the rod. Then bring over your main thread colour over the top, as shown.

Put your left thumb on the wraps, holding it secure so it won’t unravel, and cut the trim wrap thread. Bring it under the main colour thread, as shown above, and make sure it’s secure.

Continue your wrap, until you have about 6 wraps over the other loose threads. Take the loose threads in your right hand, and pull them tight. Cut them off flush, and continue wrapping.

When you are about 20 wraps away from your end point, put in one tie-off loop. Make about ten wraps around the loop, and put in a second tie-off loop.Make another 10 or so wraps.

Now put in a third tie off loop, and make another few wraps. Now you can cut the main thread, hold tension on it, and put it through the first tie-off loop you inserted.

Using the same method as with the stripping guides, pull the thread under the wraps. You now have two loops left, for your final trim wrap.

Now bring your trim wrap thread over again, and put it though the second loop you put in. Pull it tight, cut the thread, and pull it through. The thread will now be secure under the wrap. NB: Use caution so as not to pull the trim thread out from under the wraps.

We will use a different tie-off method here, just to show you.Make four wraps around the blank again, Cut the thread and pull it though the last tie-off loop. Then hold tension, and pull the entire thread length though the wrap.

Nowpull the loose tag of thread back and forth, making a “slot” in the wraps. Pull the thread tight, and put a sharp razor to it. Don’t cut it, just roll the blade against the thread. It should part neatly. Then roll and pack the thread wraps as you did with the stripping guide, to close any gaps and flatten the thread.

This tie off method is a little tricky, I would suggest using the “disappearing thread trick” instead.

The completed wrap with trims.

Here is our rod’s completed hook keeper, and decorative wraps that encase the writing. (It this case, a label we are going to stick on that came from the blank manufacturer.)

THE OTHER GUIDES:

Securing and wrapping snake guides (double foot guides) is the same as the stripping guide. For single foot guides, secure one side, and wrap as normal as well. The pic above shows the strip of masking tape that secures the guide, and the one which we placed on the blank to show the spacing.

The completed single foot guide.

You also have to wrap at least one inch of “security” wrapping on the female ferrules of the blank sections, as shown above. This ensures that the ends of the blank are secure and will not crack or split easily. If a guide is to be placed near the female ferrule, incorporate it in the securing wrap, as shown on the right.

Lastly, wrap a securing wrap of at least 1cm next to the tip-top. This will increase the strength of the blank in this section and also add a finishing touch to your rod.

END PART 4

Next time we will look at how to finish your rod.